20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Welcome to Dongguan Zhenmei Electromechanical Technology Co., Ltd.! focus on

Aluminum alloy CNC processing, CNC lathe processing,etc.

20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Zhenmei-Create value for you

CNC processing period is not timely!——

Repeated work costIQC is returned again!——

Stop working costWhy is there a problem with quality?——

Inventory turnover rate costCNC processing is small in small batches and slow proofing?——

Not match the costWhy is the dating period so long?——

Wait for costHigh product price?——

direct costLack of competitiveness——

Brand costCreate good precision parts, grow continuously

Eliminate a CNC processing error problemMulti -craftsmanship with CNC processing

Precision parts lathe processing

CNC lathe processing is a high -precision, high -efficiency automated machine tool. The monthly output can reach 300,000 pieces

Precision parts CNC processing

The processing of high -required precision parts requires a high -precision CNC machine tool

Five -axis processing of precision parts

Most of the processing processes of the product can be completed at one time to ensure the consistency of the product

CNC processing multi -surface treatment process

Multi -process coordination processing, multi -surface treatment design, good quality, good accuracyQuick proofing, parts design, structure optimization, processing and customization

Classification

Quickly help you solve the pain points of precision part customization

Power manufacturer

Quality assurance

Strict test

Strong processing ability

On time

In 1997, the GIM Corporation was established in Silicon Valley in the United States. It was led by returnee engineers and was in line with international advanced technology. So far, it has 20 years of CNC in batches of various non -standard and high -precision parts;

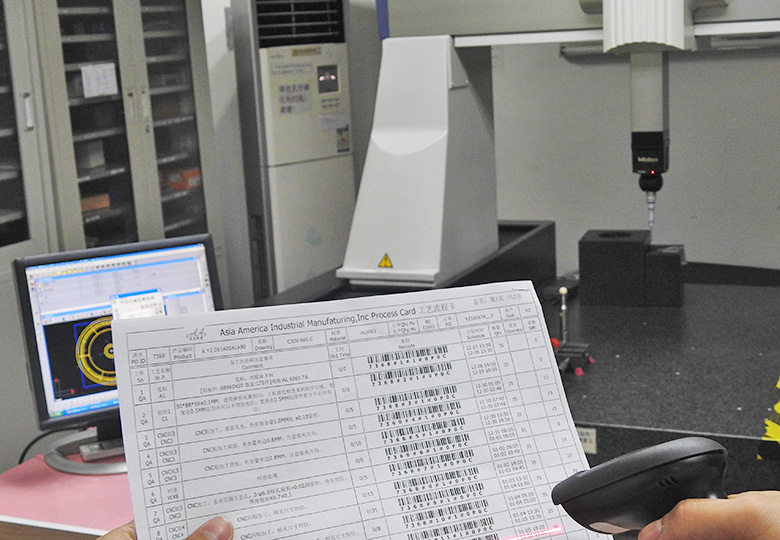

We use ERP system plus code management. Managers are elites familiar with the standards and specifications of ISO9001. Some product control processes use IoT technology to ensure the authenticity and real nature of data.

The company has a 5 -axis fully automatic coordinate measuring instrument (CMM); automated optical projector, surface roughness, Loos hardness meter, electronic inner diameter of thousands of feet. The item index is strictly controlled.

We have advanced equipment such as 5 -axis, CNC milling machines, four -axis cars, and multi -axis. Our materials include aluminum alloy, magnesium alloy, stainless steel, titanium alloy, nickel -based alloy and other special difficult processing materials.

Our surrounding supporting facilities are also very complete, including laser marking, welding, chemical etching, thermal fixed type, sandblasting, etc. can implement one -stop services. Maintain long -term cooperation with a number of large logistics companies: SF, DHL, Fedex, UPS, TNT, etc.

Selection of top 500 companies

Precision parts with up to 99.8%of the qualified rate

Appearance review

Part of the part of the part

DFM evaluation

Evaluation and manufacturing

Size recognition

Size recognition and narrowing standardization

Sample problem

Modification of proofing problems

Question point shutdown

Summary of mass production issues

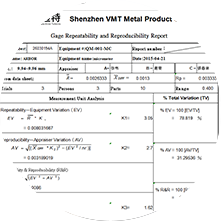

Measurement analysis

Practice according to the ritual school

reliability

Execute as required

FQC and 0QC

Perform according to AQL and standards

SPC/CKP

Process analysis of special craftsmanship

First Inspection/Inspection

Execute according to standardsUnderstand the dynamics of the enterprise and master the new wind direction

Dongguan Zhenmei Electromechanical Technology Co., Ltd.

tel:

+86 180-9828-6997address

No. 1, Wangdong, Wangdong, Wangtong Town, Wang Niutun Town, Dongguan City, Guangdong Province

Mobile website