20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Welcome to Dongguan Zhenmei Electromechanical Technology Co., Ltd.! focus on

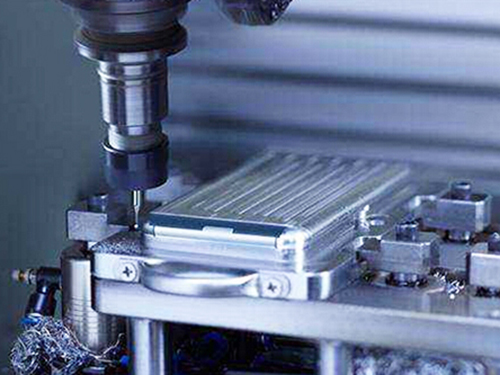

Aluminum alloy CNC processing, CNC lathe processing,etc.

20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

First of all, the common dimensional errors in precision parts processing can be dealt with by accurate measurement and control. In the process of machining, high-precision measuring equipment is used to detect the size of the parts, and the measurement results are compared with the design requirements. If the size error is within the allowable range, the processing parameters can be adjusted to correct the error; If the size error exceeds the allowable range, the processing process needs to be re-adjusted or the processing tool replaced to ensure that the size of the part meets the requirements.

Secondly, shape error is one of the common problems in precision parts processing. Shape errors include parallelism, perpendicularity, roundness and cylindricity. In order to deal with these errors, it is necessary to adopt appropriate processing technology and equipment. For example, in turning processing, sensors can be used to detect the shape errors of parts in real time, and the position of the tool can be adjusted through an automatic compensation system to achieve accurate machining requirements.

Secondly, shape error is one of the common problems in precision parts processing. Shape errors include parallelism, perpendicularity, roundness and cylindricity. In order to deal with these errors, it is necessary to adopt appropriate processing technology and equipment. For example, in turning processing, sensors can be used to detect the shape errors of parts in real time, and the position of the tool can be adjusted through an automatic compensation system to achieve accurate machining requirements.

Finally, surface quality error is a problem that must be paid attention to in the machining of precision parts. Surface quality errors include roughness, smoothness and finish errors. To deal with these errors, processes such as grinding, polishing and sandblasting can be used to improve the surface quality of the part. In addition, special coating materials can be used to improve the wear and corrosion resistance of parts to meet specific application requirements.

Error handling in precision parts machining is a critical task that needs to be carried out through accurate measurements, suitable machining processes and equipment, and appropriate post-processing methods. Only after strict control and treatment, can we ensure the quality and performance of precision parts, meet the needs of customers, and contribute to the development of modern manufacturing.

Dongguan Zhenmei Electromechanical Technology Co., Ltd.

tel:

+86 180-9828-6997address

No. 1, Wangdong, Wangdong, Wangtong Town, Wang Niutun Town, Dongguan City, Guangdong Province

Mobile website