20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

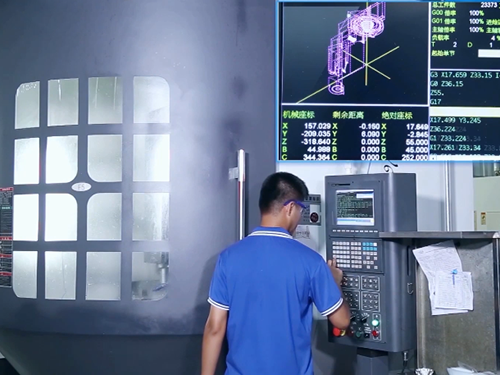

Welcome to Dongguan Zhenmei Electromechanical Technology Co., Ltd.! focus on

Aluminum alloy CNC processing, CNC lathe processing,etc.

20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Precision parts machining has been widely used in various industries. However, sometimes sealing failure occurs during machining, which brings certain troubles to production and use. So, what is the meaning of precision parts machining seal failure?

Precision parts machining seal failure refers to the problem that in the machining process, due to unreasonable design, improper manufacturing process or improper material selection, the sealing performance of parts is not up to standard. The sealing failure may be manifested as oil leakage, leakage, and lax sealing, and even cause equipment damage and increase production costs in serious cases.

There are many reasons for precision parts machining seal failure. First of all, poor design is a common reason. If the sealing structure design of the part is not reasonable, such as the sealing surface shape is not correct, improper selection of sealing materials, etc., it is easy to lead to sealing failure. Secondly, improper manufacturing process is also a common problem. If the processing accuracy is insufficient, the processing surface is rough, and the welding is not firm, etc., it may lead to the deterioration of the sealing performance of the parts. In addition, improper material selection can also lead to seal failure. If the selected sealing material is not resistant to corrosion, high temperature, etc., it is easy to leak.

In order to avoid the occurrence of precision parts machining seal failure, we can take the following measures. First of all, it is necessary to strengthen the quality control in the design and manufacturing process to ensure that the sealing structure of the parts is reasonable and the processing accuracy is up to standard. Secondly, the appropriate sealing material should be selected and strict material testing should be carried out. At the same time, it is necessary to strengthen the detection and testing of parts to find and solve potential sealing failure problems in time. In addition, regular maintenance of equipment and timely replacement of aging seals are also effective measures to prevent seal failure.

Precision parts processing seal failure is a problem that needs attention, it will not only affect the normal operation of the equipment, but also increase production costs. By strengthening the design, manufacturing and maintenance measures, we can effectively prevent and solve sealing failures, improve the quality and efficiency of precision parts machining.

Dongguan Zhenmei Electromechanical Technology Co., Ltd.

tel:

+86 180-9828-6997address

No. 1, Wangdong, Wangdong, Wangtong Town, Wang Niutun Town, Dongguan City, Guangdong Province

Mobile website