20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Welcome to Dongguan Zhenmei Electromechanical Technology Co., Ltd.! focus on

Aluminum alloy CNC processing, CNC lathe processing,etc.

20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Influence of cutting force and friction. When precision parts are machined, the extrusion and friction of the cutting edge of the tool and the side facing the workpiece can cause plastic deformation of the metal material, which causes the existing residual area to distort or deepen the groove, increase the surface roughness and lead to the processing of brittle materials. At this time, the cutting chips become broken particles, and the machined surface often shows traces of particle collapse. Many pits are left, making the surface rough.

Effect of clastoma. When the cutting tool cuts the plastic at a certain speed, some small particles on the chip will adhere to the tip of the front tool face, forming a high hardness accumulation edge, which can replace the front tool face and cutting edge. When the friction between the chip and the accumulated edge is greater than the cold welding strength between the accumulated edge and the front cutter face, or when it is impacted or vibrated, the accumulated edge will fall, so that the new up edge will gradually be formed later. The formation, growth and shedding of stacked edges will seriously affect the surface roughness of parts.

(chippings)

(chippings)

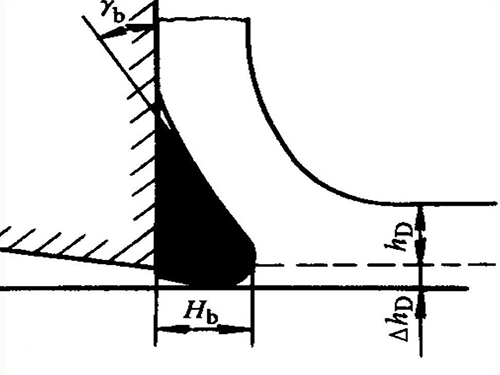

Effect of squamous spines. In the cutting process, due to the friction and cold welding of the chips on the cutting surface during the machining of precision parts, the cutting chips will regularly stay on the front tool surface, thereby squeezing the newly machined surface. In severe cases, the surface can tear. Scaly spines form on the surface, making the surface rough and uneven.

(Schematic diagram of the stages of scale-forming process)

(Schematic diagram of the stages of scale-forming process)

Due to the influence of the above physical factors on the roughness, in order to reduce the surface roughness, in addition to reducing the plastic deformation caused by the cutting force, the generation of accumulated tumors and scales is avoided during the machining of precision parts. The main process measures are: select the cutting speed that is not easy to produce accumulated edges and thorns, improve the cutting performance of the material, and correctly select the cutting fluid.

For the machining industry of precision parts processing, the purpose of formulating tolerances is to determine the geometric size of the product and make it change within a certain range to meet the requirements of interchange and use.

Dongguan Zhenmei Electromechanical Technology Co., Ltd.

tel:

+86 180-9828-6997address

No. 1, Wangdong, Wangdong, Wangtong Town, Wang Niutun Town, Dongguan City, Guangdong Province

Mobile website