20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Welcome to Dongguan Zhenmei Electromechanical Technology Co., Ltd.! focus on

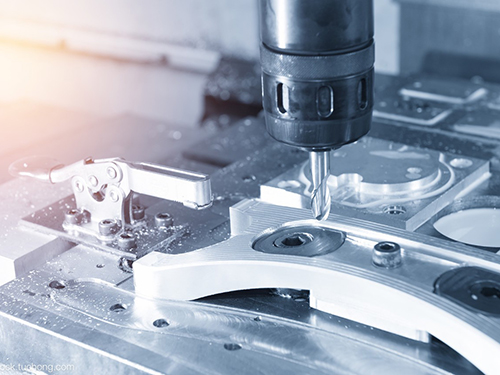

Aluminum alloy CNC processing, CNC lathe processing,etc.

20 years of precision parts processing

CNC precision part processing manufacturer-Zhenmei+86 180-9828-6997

Precision parts processing, large precision parts play an important role in various industries, and their normal operation is directly related to the stability and production efficiency of equipment. However, due to its complex structure and high precision requirements, the maintenance of large precision parts is particularly important. Let's take a look at the maintenance of large precision parts.

First of all, for the maintenance of large precision parts, regular inspection is an essential work. Through regular inspection, the wear, corrosion, cracks and other problems on the surface of the parts can be found in time, so as to repair or replace them in time. At the same time, pay attention to the inspection and replacement of lubricating oil to ensure that the lubrication of parts is good and reduce wear and friction.

Precision parts processing

Secondly, the cleaning of large precision parts also needs to be paid attention to. In the process of use, the surface of the parts will accumulate a certain amount of dirt and dust, if not cleaned in time, it will affect the normal operation of the parts. Therefore, it is necessary to clean the surface of the parts regularly. During the cleaning process, appropriate cleaning agents should be used to avoid damage to the parts. At the same time, after cleaning, it is necessary to dry in time to avoid corrosion and other problems on the surface of the parts.

In addition, the maintenance of large precision parts is also very important. Maintenance work generally includes lubrication, rust prevention and other aspects. For lubrication work, it is necessary to choose the appropriate lubricant and lubricate in accordance with the specified period and method. The lubricant should be sufficient, and pay attention to the lubrication of the lubrication point. For the anti-rust work, the appropriate anti-rust agent should be selected according to the material of the parts, and the anti-rust coating should be carried out regularly to avoid moisture and rust of the parts.

Secondly, the cleaning of large precision parts also needs to be paid attention to. In the process of use, the surface of the parts will accumulate a certain amount of dirt and dust, if not cleaned in time, it will affect the normal operation of the parts. Therefore, it is necessary to clean the surface of the parts regularly. During the cleaning process, appropriate cleaning agents should be used to avoid damage to the parts. At the same time, after cleaning, it is necessary to dry in time to avoid corrosion and other problems on the surface of the parts.

In addition, the maintenance of large precision parts is also very important. Maintenance work generally includes lubrication, rust prevention and other aspects. For lubrication work, it is necessary to choose the appropriate lubricant and lubricate in accordance with the specified period and method. The lubricant should be sufficient, and pay attention to the lubrication of the lubrication point. For the anti-rust work, the appropriate anti-rust agent should be selected according to the material of the parts, and the anti-rust coating should be carried out regularly to avoid moisture and rust of the parts.

Finally, the maintenance of large precision parts also includes storage and transportation considerations. In the storage process, pay attention to place the parts in a dry, ventilated, non-corrosive gas environment to avoid moisture or corrosion of the parts. During transportation, appropriate packaging measures should be taken to ensure that the parts are not squeezed and collided.

In precision parts processing, the maintenance of large precision parts requires our care and patience. Only by doing a good job of maintenance can we ensure the normal operation of parts, extend the service life of parts, and improve the stability and work efficiency of equipment.

Dongguan Zhenmei Electromechanical Technology Co., Ltd.

tel:

+86 180-9828-6997address

No. 1, Wangdong, Wangdong, Wangtong Town, Wang Niutun Town, Dongguan City, Guangdong Province

Mobile website